As a top UK provider of cheap toilet roll, we thought we’d share some secrets behind the manufacturing process and answer the question… how is toilet roll made?

Toilet rolls are used in our daily lives. In the bathroom, for blowing our noses, small cleaning jobs and hundreds of other tasks. But how do manufacturers do it? What is their process?

Let’s find out now, in the latest article from Galleon Supplies.

What is Toilet Roll Made From?

Toilet roll manufacturers mostly use ‘virgin’ paper. This is a combination of hardwood and softwood trees (70% hardwood and 30% softwood).

This blend of trees provides the durable materials needed for the manufacturing process.

How is Toilet Roll Made Sustainably?

The toilet roll that is made from virgin trees is, unfortunately, not a sustainably made product. However, many manufacturers have released eco-friendly alternatives made from renewable materials. Bamboo and recycled paper are among the most popular materials used.

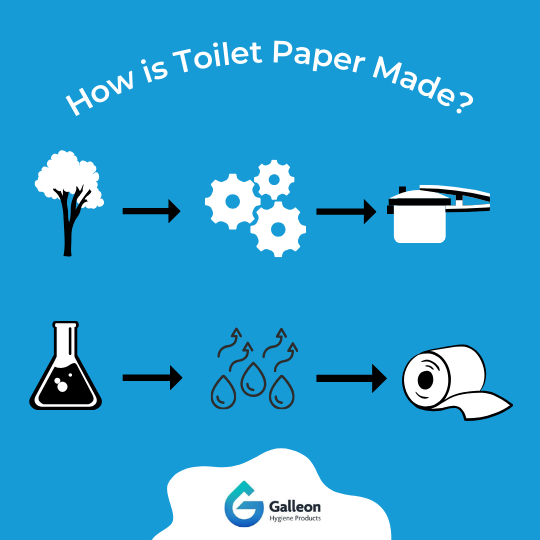

How is Toilet Roll Made? 6 Steps

Prepare:

- The trees are stripped of their bark to get the highest concentration of wood for toilet rolls. These trees are debarked with a machine in order to reduce wasted wood.

Deconstruct:

- Then, the debarked tree logs are passed through a machine to chip them into pieces. These wood chips are then separated into batches for the digesting process.

Digest:

- A digester, which is a large pressure cooker, cooks the wood chips for around three hours. Various chemicals are added to the digester to reduce the wood chips to cellulose fibres and lignin. The result of the cooking process is a usable fibre known as pulp, which in turn makes up paper.

Clean:

- Next, the pulp is washed of all of the lignin and chemicals involved during the cooking process. Once washed, the pulp is bleached to remove all colour. Without this step in the process, the toilet roll would become yellow over time. Then, water gets added and mixed into the pulp, resulting in paper stock (0.5% fibre and 99.5% water). After that, the paper stock is sprayed onto screens of mesh, draining the water from it. After being sprayed onto the mesh, the paper is then pressed and dried.

Produce and Roll:

- Using metal blades, the paper is scraped off the mesh and wound onto reels. This is then moved to machines that cut it into long strips.

Cut:

- The toilet rolls are formed and packaged.

Finally, it gets Sold to You

The last step in the toilet roll manufacturing process is for it to be sold to the consumer.

We’ve answered the question of how is toilet roll made? And now it’s time for you stock up.

Galleon Supplies is trusted by hundreds of businesses across the UK. We deliver your goods straight to your door but also deliver on quality, service and price. So, stock up on our cheap toilet rolls today for your home, school or business.

This article was written by Tim Bench of Galleon Supplies